Sketch to Steel: West Tennessee Inspires BlueOval City Sculpture

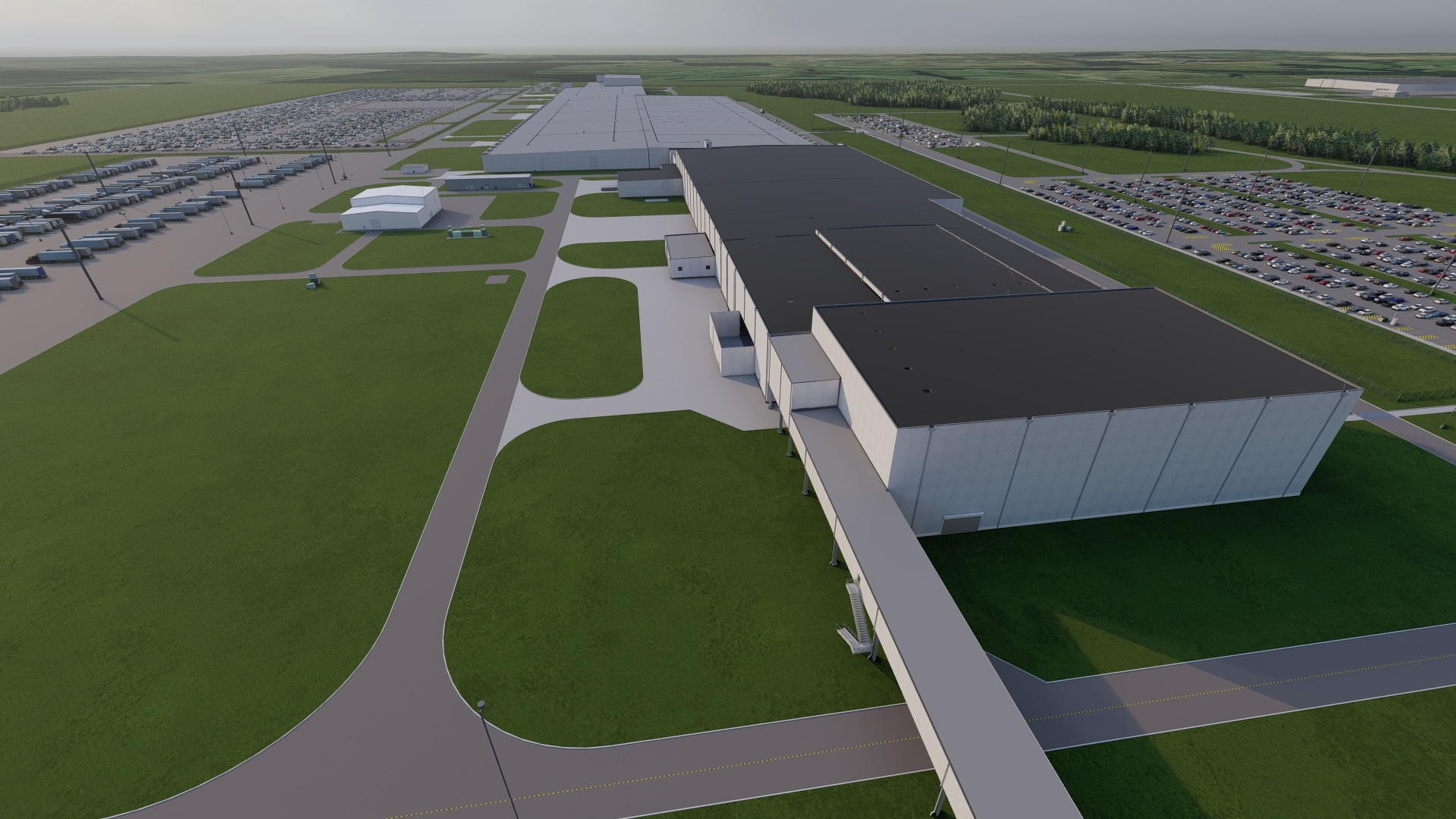

Ford, the No. 2 electric vehicle brand in the U.S. in 2022, is on track with construction at BlueOval City mega-campus and poised to usher in a new era of American innovation and manufacturing.

The electric vehicle and battery manufacturing campus in West Tennessee begins production in 2025. It will be home to Ford’s second-generation electric truck, code named Project T3, and will be capable of producing 500,000 electric trucks a year at full production.

“BlueOval City is the blueprint for Ford’s electric future around the world,” said Bill Ford, Ford’s executive chair. “We will build revolutionary electric vehicles at an advanced manufacturing site that works in harmony with the planet, aligning business growth and innovation with environmental progress.”

Ford and partner SK On are investing $5.6 billion in the campus and creating approximately 6,000 new jobs. Ford has launched a comprehensive education and training effort called BlueOval Learning to prepare future employees.

BlueOval City is designed to be Ford’s first carbon-neutral vehicle manufacturing and battery campus as Ford works to power all Ford plants globally with renewable and carbon-free electricity by 2035.

“Project T3 is a once-in-a-lifetime opportunity to revolutionize America’s truck," said Jim Farley, Ford president and CEO. "We are melding 100 years of Ford truck know-how with world-class electric vehicle, software, and aerodynamics talent. It will be a platform for endless innovation and capability.”

“Project T3 is a once-in-a-lifetime opportunity to revolutionize America’s truck.”Jim Farley, president and CEO, Ford

“PJ O’Rourke once described American pickups as ‘a back porch with an engine attached.’ Well, this new truck is going to be like the Millennium Falcon — with a back porch attached,” he said. “The manufacturing process will be equally breakthrough, with radical simplicity, cost efficiency, and quality technology that will make BlueOval City the modern-day equivalent of Henry Ford’s Rouge factory — a factory of the future that people from all over the world will want to tour.”

BlueOval City also is a key part of Ford’s plan to scale electric vehicle production and make them more accessible to customers; the company is targeting a production run rate of 2 million electric vehicles annually across the globe by late 2026.

With its F-150 Lightning, Ford already has shifted people’s expectations about the capability, driving enjoyment, and productivity electric pickups can deliver. Ford’s Project T3 aims to further grow and reinvent the Ford truck franchise.

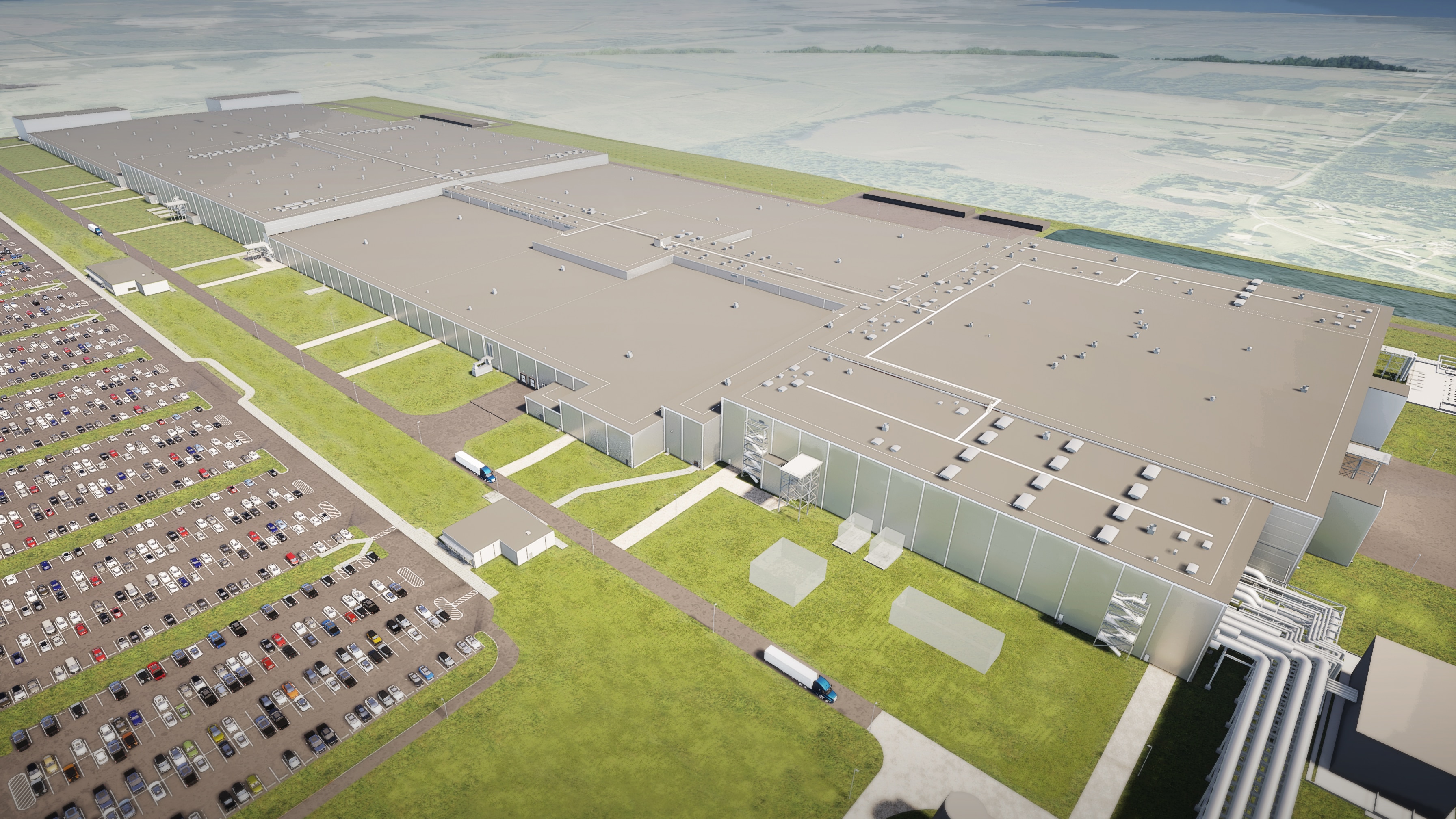

Ford is developing its second-generation electric truck in tandem with the all-new assembly plant, resulting in efficiencies never before possible, such as a 30% smaller general assembly footprint than traditional plants while delivering higher production capacity.

Meanwhile, Project T3 team members are ensuring they deliver the capability and innovation customers expect from Ford trucks with a fraction of the complexity from previous truck programs.

Project T3 is short for “Trust The Truck” — a code name that stuck after the development team made it their rallying cry. The team’s single guiding principle has been to create a truck people can trust in the digital age — one that’s fully updatable; constantly improving; and supports towing, hauling, exportable power, and endless new innovations owners will want.

The assembly plant will use carbon-free electricity from the day it opens. For the first time in 120 years, Ford also is using recovered energy from the site’s utility infrastructure and geothermal system to provide carbon-free heat for the assembly plant — saving about 300 million cubic feet of natural gas typically needed each year to heat similarly sized vehicle assembly plants.

The campus’s new utility system will save 50 million gallons of water each year by reducing evaporation from the site’s cooling towers. Plus, the zero-waste-to-landfill site is designed to use no fresh water for its assembly processes. Ford also intends to develop a holistic stormwater management system separate from the water table to help protect the local environment.

The 3,600-acre campus also has a fully integrated BlueOval SK battery manufacturing site. On-site, the team will build battery cells and arrays and assemble battery packs that will be delivered just across the site into the assembly plant in less than 30 minutes.

In addition, BlueOval City is developing an on-site supplier park and will have an upfit center capable of adding in dozens of Ford trucks’ most popular features — including robotically installed spray-in bedliners and integrated tool boxes before the pickups are released to dealers and customers.

To help reduce traffic congestion and emissions, the campus also has an on-site Lowe’s store supplying building materials, two construction equipment rental companies, and three concrete batch plants.

To prepare individuals for new jobs at BlueOval City, Ford is introducing BlueOval Learning to empower future workers to build an electric vehicle future in America. This talent development program will strengthen skills, provide teacher support, and increase work-based learning experiences.

Key elements include:

Expanding Community Support

Ford is working to ensure local touches are included in BlueOval City’s design — including crops and art.

Ford electric vehicle designers, marketers, and land development leaders are collaborating with the University of Memphis Department of Art to create a student-led art installation to serve as a landmark for BlueOval City. The piece — which is the focus of a University sculpture art course — will be installed this summer.

Native Tennessee grasses will be planted on about 500 acres to support local wildlife and select local farmers also are invited to continue planting and harvesting crops on 380 acres of the site, saved for future expansion as electric vehicle adoption grows.

Plus, Ford Motor Company Fund is leading a capital grants program to strengthen local communities’ infrastructure in West Tennessee. Local nonprofits and municipalities in the area have been selected as grant recipients, receiving a total of nearly $1.2 million to help build capacity and infrastructure to better serve the community’s needs for generations to come.

The Ford Fund capital grant winners by county:

“We are thrilled to announce the winners of our capital grants program in West Tennessee,” said Mary Culler, Ford Motor Company Fund president. “Investing in local nonprofit organizations and municipalities is one powerful way we can help ensure communities grow stronger from our presence in the region. Together, we can create new opportunities to thrive — not just for today, but for generations to come.”

Ford, Ford Motor Company Fund, and partners have now invested more than $20 million in Tennessee communities to advance economic and educational opportunities, preserve legacy institutions, and protect the environment in West Tennessee and across the state.