Our aerodynamics team spent a large portion of their careers obsessed with details that most people can’t see. More than half of our aero team came from the Formula 1 world, where air is either your greatest ally or most punishing enemy.

When you’re chasing milliseconds on a lap time, every curve and every millimeter matters.

That same obsession helped us make our new mid-size electric truck’s aerodynamic efficiency more than 15% better than any other pickup truck on the market today and will ultimately result in longer range and lower cost for our customers.1

F1 Influence: Fail Fast, Learn Faster

To bring our new mid-size electric truck to life, we didn't just look to the automotive industry for inspiration — we looked to the racetrack. By adapting a Formula 1-inspired development cycle, we shifted our focus toward a "fail fast, learn faster" mentality.

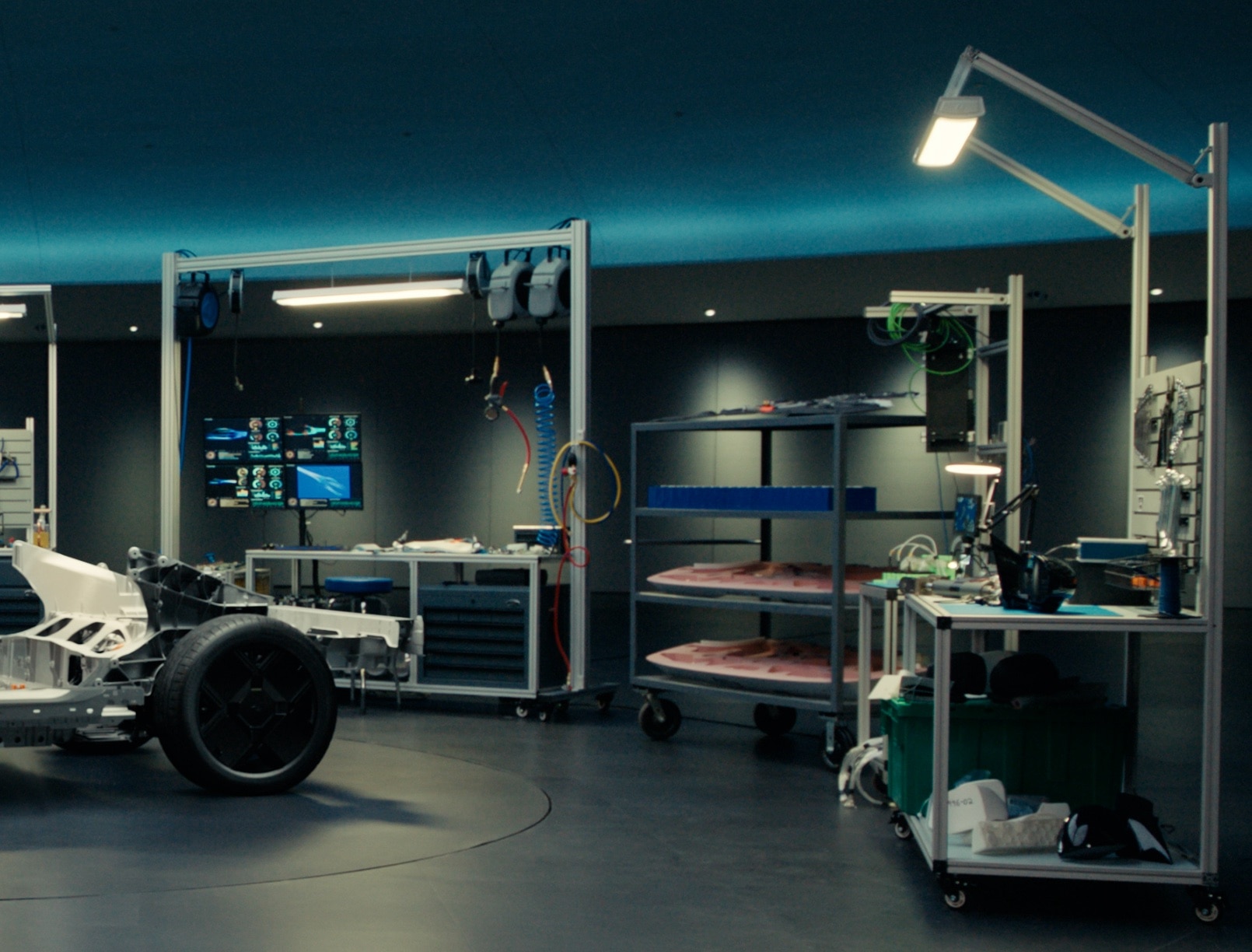

Historically, wind tunnels are used at the end of a project to validate a design and when little can be changed. We flipped that. We used the wind tunnel as a development tool as designers were just starting to put pen to paper, operating with the urgency of a race team pit crew.

To achieve this, we utilized a modular "LEGO-like" build for our test vehicle. This allowed us to swap 3D-printed and machined parts — from under-body shields to front fascia to suspension — in as little as minutes. We tested thousands of 3D-printed components, including versions of the suspension and drive units that didn't even exist as functional prototypes yet. We measured the forces that would change as a result in the vertical, longitudinal, and lateral directions on a 1.2mm steel thick car-sized treadmill that matched the air speed at 87 mph.

Since these 3D-printed parts were accurate within fractions of a millimeter of our simulations, it allowed us to develop a deeper, data-driven understanding of how every single detail impacts range and efficiency in the real world.

This rapid pace allowed us to constantly chase our "bounty targets"— the numerical metrics we use to convert efficiency improvements directly into battery savings and estimated range. It also helped us gather the data we needed to improve our simulation capabilities in a virtuous cycle designed to improve our predictive capabilities in computational fluid dynamics.

But testing faster is only half the battle; you also must think faster.

To process the massive influx of data from our increased sensor arrays, we rebuilt our aerodynamic digital toolkit from the ground up. We built modernized data pipelines and custom visualizations, creating a seamless flow of information across the aerodynamics team. Everyone, whether in Michigan or California, could see the wind tunnel data streaming in real time and compare it to simulations. And unlike in Formula 1, we weren’t limited by a rule set for how much compute, how many hours, or what type of supercomputer we could use.

These digital tools do more than just speed us up — they lay the foundation for future AI-driven design. They allow us to pinpoint exactly which changes can have the biggest impact on battery cost and range, helping us understand the "why" behind the physics. After all, air is invisible.

By applying our F1-inspired toolkit, we were able to find aerodynamic gains in places others might overlook. Here are three ways we "chased physics" to extend the range of our new electric truck:

Obsessing Over Aerodynamics

1. The Virtual Surface

We sculpted the roofline to carefully shed high-speed air in a teardrop profile that extends over the bed. This creates a "virtual surface," allowing the air to skip over the truck bed entirely. To the air, it is no longer a truck, but a sleek, aerodynamic silhouette.

2. The 1.5-Mile Mirror

Innovation often comes from simplification. Instead of using separate motors for glass adjustment and power-folding, we merged these functions into a single actuator. Now that the mirror body no longer needs internal "wiggle room" for the glass to move independently, we were able to shrink the entire housing by over 20%. This reduction in frontal area and mass unlocks a more aerodynamic shape, adding an estimated 1.5 miles of range. It doesn’t sound a lot, but these marginal gains add up.

3. Underbody Stealth

The underside of a truck is typically an aerodynamic nightmare. We treated it like a racing floor, making bolts flush to the floor in miniature pockets and painstakingly designing the underbody to guide air around the front tires and suspension. While you can’t make a tire wake disappear entirely, you can manage it. We guided the front tire wake directly toward the rear tires, effectively "hiding" the rear wheels. By preventing the rear tires from punching their own hole through the wind, we gained an additional 4.5 miles of range.

The 50-Mile Difference

This vehicle is a singular, integrated system. We couldn’t simply use an existing truck’s body; the physics wouldn’t work. To deliver on range and affordability for the customer, the body had to be meticulously sculpted from day one.

The result?

If the same battery was married to the aerodynamics of the most aerodynamically efficient mid-size gas truck in the U.S., we believe our new electric truck would have nearly 50 miles or 15% more driving range. And a 30% improvement at highway speeds.2

We’re moving into real-world testing on tracks and city streets to make sure every detail is just right. These insights will help us perfect our production and guide the next generation of our Universal EV Platform.

You might not see the air we’ve managed, but you’ll certainly feel the difference in the drive.

Saleem Merkt is Advanced EV Aerodynamics senior manager.

What to Read Next

1. Based on Ford's internal testing.

2. Based on projected aerodynamic efficiency of Ford’s new electric truck compared to a 2025 Ford Maverick truck and a 2022 Hyundai Santa Cruz truck.

Frequently Asked Questions

Q. What is the overarching approach Ford is taking to develop the Universal EV Platform?

A. We are utilizing a true systems engineering approach across design, product development, software engineering, supply chain and manufacturing. This collaborative effort completely rethinks vehicle production, with every decision centered on reducing battery size and delivering more value for money to customers.

Q. How did Ford’s design and engineering teams approach aerodynamic optimization for the new mid-size electric truck?

A. Our designers and engineers collaborated closely with our own ex-Formula 1 aerodynamicists. They worked together to ensure the truck not only looks great but performs even better. The ‘bounties’ system kept everyone focused on “chasing physics,” continuously challenging targets and resetting them for further gains, much like shaving milliseconds off lap times in racing.

Q. What specific aerodynamic innovations were implemented on the mid-size electric truck?

A. Some of the actions we took include streamlining the underbody by making bolt holes shallower and carefully directing air around the tires and suspension. The underbody design also steers the front tire wake directly onto the rear tires, effectively hiding them from high-speed flow to reduce drag. At the back, drive units were positioned low to minimize friction in half-shafts, and the motor case was sculpted to allow uninterrupted air flow, reducing wake size. The roof was sculpted in a teardrop shape to create a “virtual surface” over the bed, making it “no longer a truck” to the air. These are just a few examples.